Did you know that nearly 1 in 4 heating system breakdowns happen within the first 5 years, even with a brand-new boiler? If you’ve recently invested in the latest gas boiler or upgraded your heating system, you might think you’re set for years of worry-free warmth

Startling Facts: The Surprising Rate of Modern Boiler Failures

"Did you know that nearly 1 in 4 heating system breakdowns happen within the first 5 years, even with a brand-new boiler?"

- More than 23% of new gas boiler installations experience failures within five years.

- Over 60% of boiler breakdowns are traced to poor installation or skipped servicing rather than product faults.

- System contamination (sludge, limescale) causes a third of costly heating system repairs.

- Incorrect boiler sizing leads to short cycling and early part failures in 17% of cases.

- Many people trust "smart" boilers, yet even modern boilers require annual expert checks for warranty and safety.

What This Means for Your Heating System

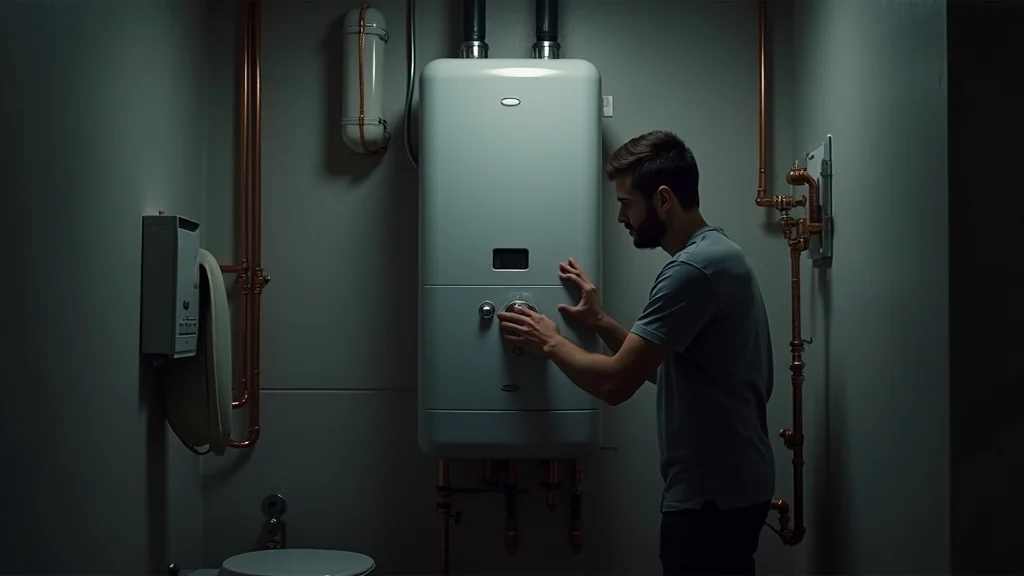

The numbers above prove that boiler problems are not a thing of the past. If you assumed that installing a new boiler would eliminate the risk of a faulty boiler, think again. Heating systems are only as reliable as the quality of their installation and ongoing care. Even robust designs can fall victim to issues like trapped air, low pressure, or contaminated central heating water. With so many moving parts and hidden connections, a single shortcut during installation or missed boiler service can mean your new heating system starts causing problems sooner than you think. Rather than trust flashy guarantees or “maintenance-free” claims, homeowners should learn what truly keeps a modern boiler running smoothly.

It's also worth noting that the standards and expertise of your installation team play a pivotal role in long-term performance. For a deeper understanding of how professional commitment and industry best practices can impact your home's systems, you may find it insightful to explore our approach to quality and reliability in every project we undertake.

What You’ll Learn About Why Modern Boilers Still Fail—and What Most Homeowners Are Never Told

- Hidden reasons behind common boiler problems

- How installation errors affect your modern boiler

- What you can do to prevent gas boiler breakdowns

- Understanding boiler pressure, hot water issues, and more

Understanding Heating Systems: Why Modern Boilers Still Fail in Today’s Homes

Types of Heating Systems and the Role of the Gas Boiler

Modern homes often feature either combi boilers, system boilers, or traditional regular boilers as the cornerstone of their heating systems. A gas boiler remains the most common type, powering central heating and ensuring hot water on demand. While heat pump technology is gaining traction, most UK households still rely on gas boilers, expecting reliability with every switch of the thermostat. Despite advances in boiler controls, efficiency, and safety features, the role of your gas boiler is as critical as ever—it’s the heart of your heating and hot water supply. The challenge is that, unlike older boilers, today’s compact units pack more sensors and digital controls into a smaller space, which can make them more sensitive to issues caused by poor installation or lack of maintenance.

Your central heating system is a network of radiators, pipes, thermostatic controls, and (in many homes) underfloor heating loops. All these components depend on the boiler performing optimally. Missed details like trapped air or a faulty filling loop can place extra pressure on your boiler, leading to strange noises, loss of heat, or inconsistent hot water—common symptoms of deeper boiler problems.

How the Modern Boiler Integrates with Your Central Heating

Central heating systems work by circulating hot water, generated by your boiler, through pipes to radiators or underfloor circuits then back to the boiler in a continuous loop. A modern boiler is designed to modulate (adjust its output) for efficiency, automatically responding to demand. However, if the installer skips key steps—flushing out debris, fitting a proper filter, or sizing the boiler according to property needs—the result can be low boiler pressure, poor hot water supply, or frequent resets. Many people are surprised to learn that even expensive boilers can develop issues within months if the surrounding heating system is not properly maintained or configured.

Put simply, the best boiler is only as good as the system it’s installed into. Improper integration between the boiler and central heating system is a leading reason why modern boilers still fail. That’s why it pays to work with certified professionals like Plumbrite, who take the big picture into account—not just the boiler itself.

| Feature | Modern Boiler | Traditional Boiler |

|---|---|---|

| Reliability (When Properly Installed) | High (10–15 years) | Medium (10–12 years) |

| Common Failure Causes | Poor installation, system contamination, missed servicing, low boiler pressure | Wear-and-tear, outdated parts, inefficient controls |

| Maintenance Needs | Annual service, system flush, pressure checks | Annual service, basic checks |

| Installation Error Risk | High (advanced controls, sensitive components) | Medium (simpler setup) |

Why Modern Boilers Still Fail—An Expert Look at the Unseen Issues

Boiler Problems That Lurk Beneath the Surface

- Poor installation practices

- System contamination

- Incorrect boiler sizing

- Overlooked central heating system issues

Despite glossy marketing, many modern boilers are vulnerable to the same failures that plagued older boilers if not installed or maintained correctly. Poor installation practices—such as incorrect pipework, skipped system flushing, or failing to set operating pressure—can cause a new boiler to develop issues quickly. Sludge and limescale from an old central heating system can silently clog the new boiler’s heat exchanger, triggering repeated lockouts, noisy operation, and even early boiler failure. Even small errors—like a slightly misaligned condensate pipe—put stress on components and can be hard to diagnose without a gas safe registered engineer.

Incorrect sizing is another silent culprit. When a boiler is too large for the home, it “short cycles”—switching on and off repeatedly—and wears itself out. When it’s too small, it struggles to keep up, often resulting in weak hot water and cold spots in your heating system. No matter how advanced the features, no boiler can overcome the fundamental problems caused by poor installation or ill-matched hardware.

The Hidden Impact of Skipping Regular Servicing on Your Heating System

"A modern boiler might look efficient on paper, but without expert installation, it’s susceptible to the very same failures as older models." — Plumbrite Expert

Manufacturers recommend an annual boiler service for good reason—it’s essential for safety, efficiency, and catching issues before they become expensive emergencies. Yet many people put off routine checks, forgetting that modern boilers rely on sensitive electronics and pressure sensors. Skipping servicing may void warranties and leave you unprotected if boiler problems arise, especially with gas boilers. With care, your heating system can provide years of reliable hot water and warmth—but neglect is one shortcut you’ll pay for in the long run.

Installation Nightmares: Poor Practices Leading to Boiler Problems

Case Study: How Incorrect Boiler Sizing Causes Chronic Failures

” The result? Chronic short cycling, a noisy system, repeated boiler pressure drops, and energy bills that soared due to inefficient operation

In another example, a seemingly minor shortcut—failing to flush out the central heating pipes of debris—caused a brand-new gas boiler to clog within months. The homeowner, expecting years of comfort, ended up calling engineers for frequent repairs. These issues could have been avoided if the installer had followed the latest industry guidelines. In both cases, homeowner expectations clashed with reality, leading to frustration and unnecessary expense.

Why Gas Boiler and Central Heating System Installation Standards Matter

Gas boilers must be installed by a gas safe registered engineer, but not all installers are equally thorough. True professionals will check the heating system for trapped air, flush old sludge, set the correct boiler pressure, and fit essential filters. They also ensure every boiler manual is followed for setup, reducing the risk of missed “gotchas” that lead to boiler problems later. Skipping steps may shave hours from the install—but it costs homeowners more in breakdowns and lost warranty protection in the long run. Standards exist for good reason: to protect you, your investment, and your home’s heating and hot water supply.

- Checklist—Signs of Poor Installation in Your Heating System:

- Unusual noise (gurgling, banging, whistling) in pipes or radiators

- Inconsistent or weak hot water from taps

- Low boiler pressure indicated on the pressure gauge

- Unexplained resets or “faulty boiler” warnings

- Trapped air that persists even after bleeding radiators

- Boiler switches off unexpectedly or pilot light keeps going out

- Poor heat distribution—some rooms always cold

System Contamination: Silent Enemy of the Modern Boiler

How Sludge, Debris, and Limescale Sabotage Your Heating System

System contamination refers to the build-up of black sludge (corroded metal), white limescale, and other debris inside your central heating pipes, radiators, and heat exchanger. Even a new boiler can be quickly sabotaged by residue left from an old heating system. These impurities restrict water flow, decrease boiler efficiency, damage components, and often trigger common boiler problems such as cold radiators or poor hot water. Over time, debris can build up in crucial parts like the heat exchanger or pump. This results in higher energy bills, reduced comfort, and eventually a faulty boiler that may need costly repairs—or in extreme cases, total replacement.

Limescale, especially in “hard water” areas, is notorious for blocking pipes, choking narrow passages inside modern boilers, and messing with sensors. The only way to prevent these issues is to make sure your heating system is protected from the start, otherwise you risk silent and progressive damage that won’t show up until it’s too late.

Protecting Your Gas Boiler: Best Practices Against System Contamination

Prevention is key. Always insist on a full power flush before any new boiler is fitted, and ask your installer to fit a high-quality magnetic filter as an extra safeguard. Inhibitor chemicals should be added to slow down future corrosion. Even with these protections, you must arrange at least an annual boiler service so that any signs of early contamination are caught and treated. Regularly check the pressure gauge, bleed radiators to release trapped air, and listen for strange noises—early indicators of system health problems.

The Crucial Role of Boiler Pressure and Pilot Light in Modern Boiler Failures

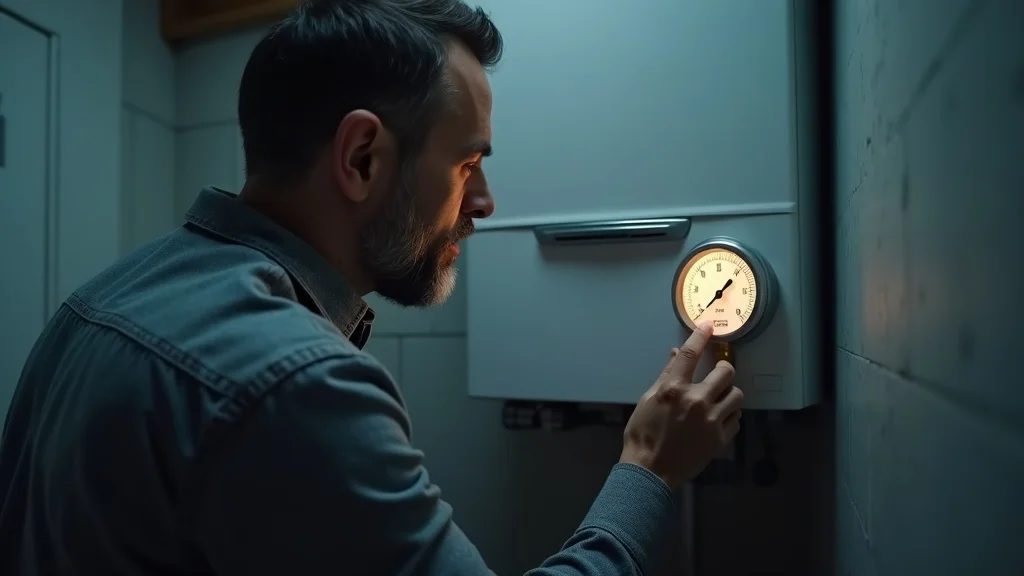

Boiler Pressure Mistakes Most Homeowners Miss

Boiler pressure is the unsung hero of a working gas boiler. Too high, and you risk dangerous leaks or constant releases from the pressure valve. Too low, and your heating and hot water may stop altogether—resulting in cold showers and chilly nights. Many people do not realise that something as simple as a small undetected leak or a missed topping up with the filling loop can cause their modern boilers to enter fault mode. Most systems run best between 1 to 1.5 bar (check the pressure gauge front and centre of your boiler). Consistently ignoring low pressure weakens internal seals, damages sensors, and can shorten your boiler’s life by years.

It’s crucial to address pressure drops immediately, not just reset the boiler and forget. Consult your boiler manual and call a registered engineer if you notice recurring problems. Boiler pressure shouldn’t fluctuate wildly—if it does, it’s a sign something in your central heating system needs attention. Being pro-active now pays off for years down the line.

Pilot Light and Condensate Pipe: Overlooked Points of Failure

The pilot light serves as a vital safety and ignition feature in many modern and older boilers. If the pilot light keeps going out, it’s not just an inconvenience—it’s a warning sign. Possible causes include a faulty thermocouple, poor gas pressure, a blocked condensate pipe, or system contamination. Newer boilers often use electronic ignition but still have delicate parts that need to be checked and cleaned. The condensate pipe is another potential failure point, liable to freezing in winter or becoming blocked by debris. When this happens, your heating system may shut down completely to prevent flooding or backflow, leaving your home cold and your boiler unresponsive until the issue is fixed.

| Symptom | Likely Cause | Recommended Fix |

|---|---|---|

| No heat or hot water | Low pressure, trapped air, boiler manual not followed | Check pressure gauge, bleed radiators, call engineer if problem persists |

| Pilot light keeps going out | Blocked condensate pipe, faulty component | Clear pipe obstruction, engineer service |

| Strange noise (gurgling, banging) | Trapped air, limescale or sludge build-up | Flush system, add inhibitor, professional power flush |

| Boiler switching off unexpectedly | Insufficient pressure, faulty safety sensor | Check the pressure, reset, call service if unresolved |

Hot Water Woes: Why Even New Boilers Struggle

Problems with Hot Water in Modern Boiler Systems

Inconsistent hot water—or waiting ages for it to run warm—can be a real headache, especially when your new boiler was supposed to be hassle-free. Modern boilers depend on a fine balance between system pressure, water flow, and correct timing set-up. Problems in any of these areas, such as airlocks, a blocked heat exchanger, or a faulty diverter valve, often stem from installation errors or missed servicing. If your “smart” heating and hot water controller stops producing the warmth you expect, don’t just blame the unit itself—trace the issue back to the health and cleanliness of the whole heating system.

Some boilers appear to work fine for central heating but struggle to deliver steady hot water. This points to underlying issues in the plumbing layout or a problem with how the gas boiler interacts with your home’s water supply.

Central Heating System and Hot Water: Interdependencies

Did you know that hot water quality often reflects the state of your central heating system? Trapped air, fluctuating boiler pressure, or a contaminated system can all lead to poor hot water performance, even with a brand-new model

People Also Ask: Answering the Top Questions About Boiler Problems

What is the most common cause of boiler failure?

The majority of boiler failures are traced to poor installation, skipped annual servicing, and system contamination that overwhelms even robust modern boiler designs.

What will replace gas boilers in 2025?

Heat pumps and hybrid central heating systems are gaining favour as replacements for gas boilers, aiming for improved efficiency and lower emissions, but still require strict installation standards to avoid similar problems.

How long should a modern boiler last?

A well-installed and regularly serviced modern boiler can last 10–15 years, but neglecting system care may reduce this lifespan drastically.

Which boiler is most likely to explode?

While explosions are rare, boilers with persistent pressure issues or faulty safety features, particularly old or badly maintained gas boilers, pose higher risks.

Modern Boilers vs. Homeowner Expectations: Why Disillusionment is Common

Product Promises Versus Real-World Results — The Gap in Heating System Reliability

"Manufacturers tout efficiency and reliability, but the real-world lifespan of a modern boiler depends on much more than a spec sheet."

When buying a new boiler, homeowners are shown impressive brochures full of statistics about efficiency, reliability, and lifespan. Yet the reality in UK homes frequently falls short—boiler problems, pressure drops, unreliable hot water, and unexpected breakdowns remain common. The truth is, the gap between product promises and heating system reality is driven by what happens after the sale. Poorly executed installation, lack of system upgrades, or missed boiler servicing lead to disappointment. Savvy homeowners now realise what matters most isn’t boiler brand or price, but the expertise and standards of those who install and care for their heating system.

Expert Tips: Protecting Your Modern Boiler from Failure

- Arrange regular boiler pressure and heating system check-ups

- Insist on installation by certified professionals

- Address hot water problems at the first sign

- Never ignore pilot light or condensate pipe warnings

Preventive Maintenance Checklist for Homeowners

- Book an annual boiler service with a Gas Safe registered engineer

- Bleed radiators each autumn to remove trapped air

- Check the pressure gauge at least monthly; top up as needed following the boiler manual

- Listen for strange noise and investigate any sudden changes in heating/hot water

- Ask for a magnetic filter and inhibitor chemicals during installation or system upgrades

- Test the pilot light and ensure condensate pipe is insulated from freezing

FAQs: Why Modern Boilers Still Fail—And What Most Homeowners Are Never Told

-

Should I replace my old central heating system when installing a new boiler?

If your system is over 15 years old, replacing it alongside the boiler may prevent contaminants and ensure optimal performance with your new modern boiler. -

Will a filter or inhibitor stop all contaminants?

While filters and inhibitors offer substantial protection, they’re not foolproof. Annual boiler service and regular system checks are still needed for total reliability. -

How quickly can a boiler pressure issue escalate?

Pressure problems can worsen in days or even hours, leading to emergency shutdowns or component failures if left unresolved—don’t wait to act if the gauge is wrong.

Key Takeaways: What Every Homeowner Should Remember About Modern Boilers

- Modern boiler failures are often preventable with the right approach

- Installation quality and system health trump brand and model

- Plumbrite is your partner for heating system reliability

Final Thoughts: Raising the Bar for Modern Boiler Reliability

Why standards and regular expert care are non-negotiable

No matter how advanced modern boilers appear, lasting reliability hinges on expert installation, rigorous system care, and standards-driven maintenance. Homeowners who take action early save money and avoid the traps behind most boiler problems.

Take Action to Protect Your Modern Boiler Now

"Don’t wait for your boiler to fail. Contact Plumbrite today for all your plumbing and heating needs—07933830316"

If you’re ready to go beyond the basics and truly future-proof your home’s comfort, it’s worth considering how a company’s dedication to quality can make all the difference. At Plumbrite, our commitment extends far beyond installation—we believe in building lasting relationships and delivering peace of mind through every stage of your heating system’s life. Discover how our values and expertise set us apart by learning more about our unwavering approach to customer care and digital success. Take the next step towards a warmer, more reliable home by exploring what makes our service truly unique.

Add Row

Add Row  Add

Add

Write A Comment