Did you know that your chance of a boiler breakdown rises by up to 20% as temperatures drop? Sudden boiler failure during a frosty snap puts families in crisis mode—without heat, without hot water, and stuck waiting for help. Yet most breakdowns are preventable. Drawing on Plumbrite’s trusted expertise, this comprehensive guide unpacks the real reasons boilers break in winter for a reason—here’s how to stop it happening to yours, and shares step-by-step strategies to keep your home warm even when winter bites hardest.

A Startling Fact: Why Boiler Breakdowns Surge in Cold Weather

"Research shows that as temperatures drop, the rate of boiler breakdowns can increase by up to 20%." – Plumbrite Technical Operations Lead

Each year, the first big freeze leads to a flood of panicked calls for boiler repair. The cold weather isn’t just a backdrop—it’s a major player in why boiler breakdown rates spike so dramatically. When outside temperatures plunge, heating systems run longer and harder, which means boilers face more demand at higher intensity than at any other time of the year. This relentless workload exposes weak points in central heating systems, especially if maintenance has been overlooked or small issues ignored. Add in the risk of frozen condensate pipes—a notorious problem for UK homes with modern gas boilers—and you get a recipe for mechanical failure right when you need heat most.

Plumbrite’s engineers routinely see the same patterns: freezing temperatures push boilers beyond their limits, and neglecting annual boiler service means tiny faults grow into winter disasters. Fortunately, with insight, awareness, and regular care, these breakdowns can be stopped before they start.

What You'll Learn About Boilers Break in Winter for a Reason—Here’s How to Stop It Happening to Yours

- The main causes behind boiler break and breakdowns in winter

- Preventative steps to avoid a broken boiler during cold weather

- How to respond if your boiler breaks

- When to seek boiler repair or cover

- Plumbrite’s expert guidance on boiler servicing

Understanding Boiler Breaks: Why Do Boilers Break in Winter?

Cold Weather and Boiler Break: The Science Explained

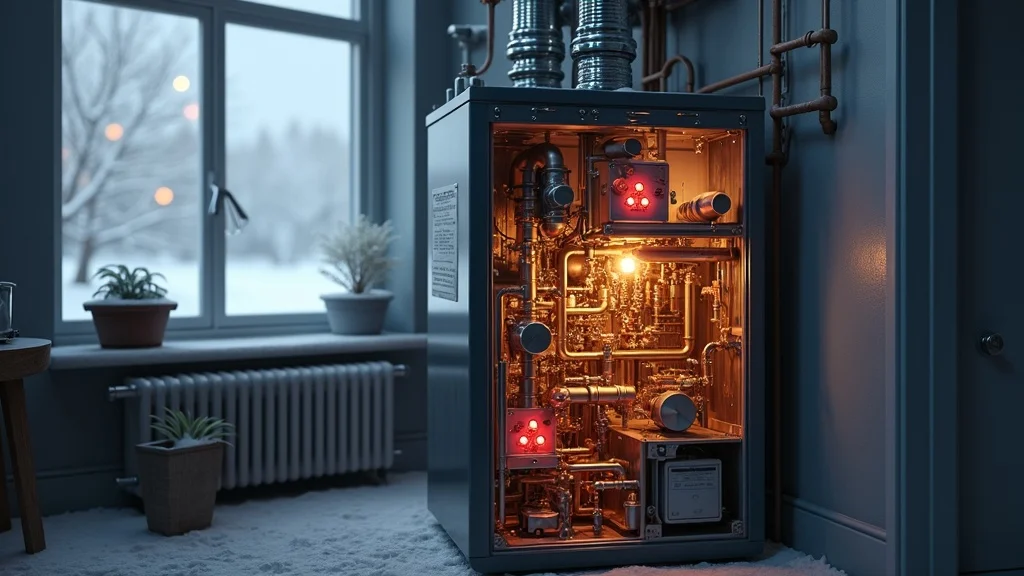

When winter hits, boilers become the lifeblood of home comfort—but cold weather brings hidden risks. The low temperature outside causes water in exposed pipes to cool rapidly, increasing viscosity and putting strain on your central heating system. This extra work is compounded by faucets running hot more often, radiators working overtime, and the heating staying on for longer periods. Even the most reliable gas boiler can be pushed to its limits.

In colder months, internal components expand and contract rapidly, seals become brittle, and electronic sensors are bombarded with condensation and temperature swings. Small, ignored cracks or limescale build-ups become aggravated failures. Plumbrite’s registered engineers emphasise that these unique winter stresses make it essential to have your boiler serviced annually. Without this check-up, micro-faults grow into breakdowns—often just when you need your heating most.

Frozen Condensate Pipe and Boiler Breakdowns

One of the leading reasons boilers break in winter is the humble condensate pipe. Modern condensing boilers expel acidic waste water through this pipe to the drain outside. But as soon as the temperature dips below freezing, any exposed section of pipe can freeze solid. This blockage triggers a shutdown: your boiler may display an error code, refuse to fire, or worst of all, overflow internally, causing water leaks or electronic failures.

Plumbrite’s professional advice is to insulate the condensate pipe wherever it runs outdoors, using foam lagging thick enough to withstand British winter nights. If you hear strange gurgling or see dripping from the boiler, check the pipe for ice—or watch for the telltale error code on the display. Ensuring your boiler installation is done by a Gas Safe registered engineer helps guarantee external pipes are positioned for maximum protection. If your pipe has already frozen, follow safe de-icing methods or call in the experts.

Boiler Pressure Issues in Colder Months

Pressure drops are another winter-specific culprit of the infamous boiler break. As radiators work overtime, tiny leaks in valves or the system’s pressure relief components are worsened, causing the needle to drop. If boiler pressure gets too low, a modern gas appliance will automatically shut down to protect itself—leaving you without heat or hot water. Alternatively, over-pressurisation from expansion can trip safety valves or damage parts, especially after a sudden freeze.

Always keep an eye on the pressure gauge, especially if your home has experienced recent radiator bleeding, or you notice water under the boiler install. Plumbrite’s annual boiler service includes a full system pressure check. At home, you can learn to safely top up pressure or read the user guide—if in doubt, get professional help fast to head off a looming boiler breakdown.

Common Signs Your Boiler Is about to Break During Winter

- No heat or hot water

- Unusual noises: banging, gurgling, whistling

- Loss of pilot light

- Low boiler pressure

- Error codes or warning lights

Major Causes Behind Boiler Breakdown in Winter

Condensate Pipe Freezing and How to Prevent It

The freeze-prone condensate pipe is public enemy number one for boiler breakdown in the UK’s cold snaps. Running externally, even briefly, it’s often overlooked during boiler install. When overnight temperatures dip, water inside can quickly freeze, leading your boiler may lock out and leaving you without heat. Insulate all visible outdoor condensate pipes using pipe foam or proprietary lagging sleeves; in extreme cases, discuss rerouting or fitting a trace heating cable with your registered engineer. Always check for leaks or drips after a thaw, and test the runoff is clear before the next storm hits.

The Role of Infrequent Boiler Serviced Schedules

Skipping or delaying your annual boiler serviced appointment is risky—especially before winter begins. Small faults, like worn seals or a weak ignition, won’t fix themselves. When the system is forced to run at full tilt in the cold, worn or dirty components are more likely to fail. Plumbrite’s gas safe register engineers catch such issues in advance, cleaning, tightening, and recalibrating as needed. Their detailed multi-point inspection, including efficiency checks and carbon monoxide testing, is the best defence against boiler breakdown.

Faulty Boiler Pressure and Component Wear

Components inside your boiler—pressure sensors, fans, igniters—are engineered to last for years, but only with maintenance. In winter, enormous swings between hot and cold can accelerate wear and tear. If you notice your radiators aren’t heating evenly, or your boiler is cycling on and off erratically, pressure regulation failure or a failing pump could be to blame. Catching these problems during a boiler service ensures parts are replaced before total breakdown sets in, keeping your central heating system running smoothly through winter’s worst.

| Cause | What Happens | Prevention |

|---|---|---|

| Frozen Condensate Pipe | Error codes, shutdown, leaks | Insulate pipe, expert installation |

| Low Boiler Pressure | No hot water, pilot light loss | Monitor, top up, annual boiler service |

| Lack of Service | Component failure, loss of output | Yearly professional boiler service |

Proactive Steps: How to Stop Boiler Breaks Before They Start

Importance of Regular Boiler Servicing and What It Covers

Getting your boiler serviced annually by a Gas Safe registered engineer is the single best way to avoid winter breakdown. Plumbrite’s experts perform a complete system examination: cleaning burners, checking venting and flues, tightening loose electrical connections, and meticulously testing for gas leaks. Regular checks keep your appliance efficient and safe, and many manufacturers require proof of service for warranty coverage. An annual boiler serviced also provides peace of mind, allowing small issues to be fixed before the cold exposes them. Book early, before the first frost hits.

Insulating and Protecting Your Condensate Pipe

Insulate every inch of the condensate pipe running outdoors to prevent winter freezes. You can use thick foam lagging, available at hardware shops, and secure it neatly around the pipe—cover bends, joints, and exposed sections carefully. For pipes with a history of freezing, ask Plumbrite about fitting a low-wattage heat trace or rerouting internally. Insulating your condensate pipe is a straightforward, cost-effective step, and ensures your heating won’t give out during an icy spell.

Monitoring Boiler Pressure in Freezing Temperatures

Keep a close eye on your boiler’s pressure gauge all winter long. Most systems run best between 1.0 and 1.5 bar. If you see the needle dipping, consult your user manual to safely repressurise, or call a Gas Safe registered engineer if pressure loss persists. After bleeding radiators, always check the gauge. Preventing low pressure preserves your heating and stops safety features from switching your boiler off. Regular boiler service appointments include pressure checks and top-ups by a registered engineer.

Why Boiler Cover Saves You from Winter Woes

Boiler cover provides instant access to repairs in the event of a breakdown. With competitive plans from Plumbrite, you won’t be left in the cold, panicking about the next step. Cover plans typically include annual servicing, priority callouts, and labour costs—making budgeting for boiler repair predictable and stress-free. Especially in unpredictable British winters, boiler cover means your home will never go without heat for long.

How to Perform Basic Boiler Pressure Checks

Emergency Actions: What to Do When Boilers Break

- Check for common issues (pilot light, pressure, error codes)

- Reset your boiler according to manufacturer’s instructions

- Call Plumbrite for rapid boiler repair

People Also Ask: Boilers Break in Winter

Why do boilers always break in winter?

Cold weather causes additional strain on boilers, increases demand, and can freeze external pipes, leading to more frequent boiler breakdowns.

How long can you be left with a broken boiler?

It depends on the responsiveness of your service provider. With Plumbrite, emergency boiler repairs are typically attended to within 24 hours.

What is the biggest cause of boiler breakdown?

Frozen condensate pipes and lack of regular boiler servicing are leading causes, especially during winter.

How to keep a house warm when the boiler breaks?

Use electric heaters, close curtains, insulate doors, and place towels at the bottoms of doors for draft protection while awaiting boiler repair.

Expert Boiler Tips from Plumbrite

- Schedule boiler serviced annually before winter

- Insulate exposed condensate pipes

- Monitor and maintain boiler pressure

- Consider comprehensive boiler cover for peace of mind

"An ounce of prevention can save you a winter’s worth of headaches and freezing nights." – Plumbrite Engineer

FAQs on Boilers Break in Winter for a Reason—Here’s How to Stop It Happening to Yours

-

How can I tell if my condensate pipe is frozen?

Look outside for icy build-up on the pipe. If the boiler is showing an error code, or you notice gurgling, check the pipe for blockages at bends or the outlet where it drains. -

Do I need boiler cover if my boiler is new?

Even new boilers can break if unforeseen conditions arise. Boiler cover provides peace of mind—especially in winter—covering emergencies and annual servicing. -

Is DIY boiler repair safe?

No—always call a Gas Safe registered engineer for any boiler repair. DIY attempts risk safety, legal compliance, and voiding insurance policies. -

How often should a gas boiler be serviced?

Gas boilers should be professionally serviced once a year, ideally before winter, to identify and repair small issues before they cause winter breakdowns.

Key Takeaways for Preventing Boiler Breakdown

- Boilers break in winter for a reason, mainly cold weather and neglect

- Regular servicing, practical precautions, and quick response are vital

- Plumbrite provides trusted, expert assistance all season long

Add Row

Add Row  Add

Add

Write A Comment